The manufacturing process of wood veneer

Veneer is the name given to the thin sheets of wood that go into the makeup of Oberflex wood products. It comes from a tree trunk that has been cut into thin layers of a few tenths of a millimeter. In the professional jargon, this step is called slicing. Many steps are required before a tree trunk (also called log) is transformed into veneer.

Choosing the wood

Choosing the right wood to be sliced and transformed into veneer is a process that requires a lot of care, experience and skill. It is a very important step that determines the production and quality of the veneers. To produce quality veneers, the logs are inspected individually based on different criteria: straightness, visible defects on the surface of the bark, size (length and diameter), color, shape... The part of the tree that can be sliced is located between its base and the first branch.

Slicing preparation

Once the logs arrive at the slicer's production site, they are prepared for slicing. They are first stripped off their bark and then steamed in hot water baths to soften the wood fibers and ensure a smooth and perfect slicing quality.

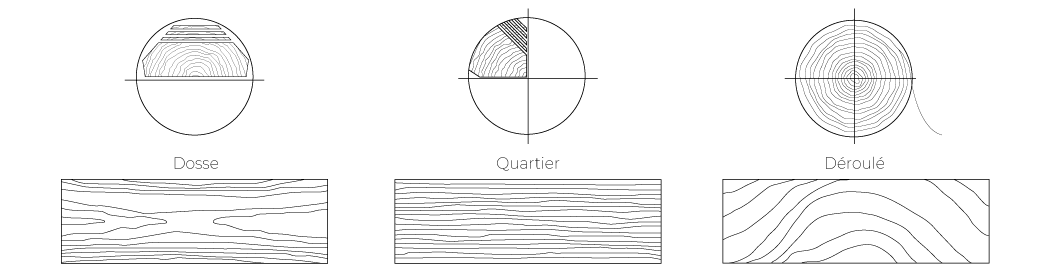

Types of slicing

After steaming, the logs can be cut into thin layers of wood. They can either be peeled or sliced. For peeling, the log is placed parallel to a fixed knife along its entire length. It is mechanically held in its center and rotates on itself. Like a pencil sharpener, the veneer in permanent contact with the knife is unrolled continuously. Slicing can be rotary, vertical or horizontal. Rotary slicing is the most impressive method. The tree trunk cut into quarters rotates around its own axis against a fixed knife. Each turn produces a sheet of veneer. For vertical or horizontal slicing, the logs are firmly held, by suction or with claws, on a moving table that moves up and down or from right to left. A veneer sheet is produced each time the log brushes against the machine's knife.

Depending on how the log is cut before slicing and the slicing method used, a different pattern will appear on the veneers.

Plain slicing: produces a cathedral grain pattern. The veneer is said to have a leafy pattern.

Quarter slicing: produces a linear pattern. The veneer is said to have a straight-grained pattern.

Rotary slicing: produces a random grain pattern.

Drying

After slicing, the still warm and wet veneer sheets are dried individually. Before and after drying, it is critical to always stack the veneer sheets in the order in which they were produced. Because if the sheets are also used in this order afterwards, that will contribute in creating a harmonious wood pattern.

Yield

To produce high-quality real wood surfaces, wood slicing is the most decorative and, at the same time, the most cost-effective method. Up to 2000 m² of veneer can be produced from one cubic meter of wood. No other method of wood processing can compete with slicing and save natural resources in a more sustainable way.