Bespoke concrete furniture and pieces

Since its creation, Concrete LCDA has relied on the fact that concrete can help to establish contemporary atmospheres for the arrangement of interior spaces. Our exclusive Beton Lege® technology, plus with our perfect mastery of solutions dedicated to interior design, have made us the benchmark in the field today. We put our expertise to work for you, in the form of retail units, kitchen countertops, bathroom sinks and other exceptional furnishings.

Concrete is a very contemporary mineral material, that contributes to creating a high-end atmosphere.

Concrete LCDA has an in-house R&D team that designs bespoke concrete furniture for interior design: concrete counters, front desks, retail displays, worktops, tables, and the list goes on. We produce objects ranging from the simplest to the most complex and come up with solutions suited to any idea.

Retail units

Our collaborations with many agencies in the commercial architecture sector have given us an understanding of shops’ expectations in terms of customizations, effectiveness and adaptability of our technologies. We have recognized expertise in manufacturing bespoke elements of retail design like welcome desks, counters, display units, bars and more.

Because every project is different, our R&D team works to devise a suitable response, tailored to each project’s needs.

Kitchen countertops

For several years now, we have enjoyed a reputation as the specialist in fibre-reinforced kitchen countertops. Our Beton Lege® technology means we can create large-scale worktops that incorporate cut-outs and other options.

Concrete is a mineral material that is well-suited to a multitude of kitchen styles, including contemporary, traditional and more. Our concrete countertops are highly resistant thanks to the resin-based surface treatments we apply to them. Unlike polished concrete and concrete coatings, fibre-reinforced concrete is suitable for the world of kitchens (with their inherent heat, humidity, etc.), whilst offering the same protections as any other mineral material.

Our raw concrete countertops are manufactured in factories under optimal drying conditions. To guarantee optimal quality, nothing is made on site.

| Thickness | Our countertops come with a standard thickness of 50 mm. Custom thicknesses are also possible, between 40 and 150 mm. Please contact us for more information. | ||||

| Concrete kitchen sinks | We do not believe concrete to be suitable for kitchen sinks. Instead, we prefer to use stainless steel basins, which are more supple. | ||||

| Appearance |

Two types of textures are available: smooth mineral and vitrified authentic raw. For each project, we work with our clients and partners to determine technical feasibility and choose finishes and colours. Our R&D team then produces technical plans and 3D images for approval.

|

||||

| Other options |

Our mastery of concrete moulding allows us to offer you a wide array of customization options. For example, we can provide cut-outs for power sockets, food trays, cooking hobs, etc. We can also manufacture legs to conceal the sides of kitchen units. |

Bathroom sinks

As a material, concrete is particularly well-suited to a designer bathroom layout, and a concrete sink adds a nice touch of minerality to any bathroom. Our concrete bathroom sinks can be installed on a vanity or attached directly to the wall!

Our very high quality of finishes yields silky soft concrete, while our unique technology ensures the material is non-porous. Thanks to our exclusive treatment, our concrete is resistant to both heat and humidity (unlike units made of concrete coating or polished concrete, which can crack). Our concrete bathroom sinks can also be used in public washrooms like those at hotels, restaurants, etc. There are almost no limits on the possible dimensions and shapes.

For each project, we work with our clients and partners to determine technical feasibility and choose finishes and colours. Our R&D team then produces technical plans and 3D images for approval.

Please don’t hesitate to contact us for more information.

Our expertise for your projects

Concrete LCDA has technological solutions for any project. Between our proprietary Beton Lege® technology and UHPC (ultra-high performance concrete) techniques, we have invested in research to make even the most ambitious projects a feasible reality.

Beton Lege®, lightweight concrete furniture

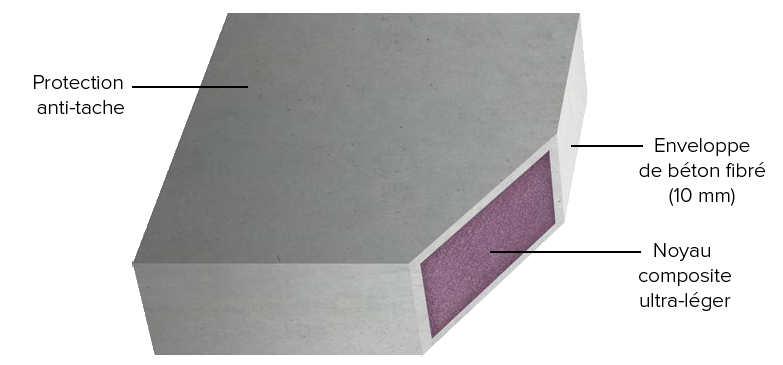

Our exclusive Beton Lege® technology divides the weight of concrete parts by three on average.

Thanks to our Beton Lege® technology, we are constantly pushing the limits of the material. Concrete is lighter and thinner. We can offer our customers all-new shapes and designs through this technology made of concrete and composite materials.

The composite core coated with 10 mm fibre-reinforced concrete achieves an average weight of 40 kg/m². Beton Lege® is an ultra-high performance, greatly lightened concrete structure with an effective treatment that protects against marks and scratches (unlike fragile polished concrete and concrete coatings). The material is no longer fighting against its own weight, giving artists, designers and architects the freedom to create now feasible daring designs.

UHPC, ultra-high performance concrete

Create exceptional pieces thanks to UHPC (ultra-high performance concrete), which delivers significant compression resistance that is six times greater than that of traditional concrete. The other techniques used, including solid concrete and concrete shells, open up numerous possibilities thanks to their great adaptability. In the case of a solid shell, this is a monolithic seamless mass.

A qualified R&D team

Our R&D team of experienced designers can create exceptional pieces in line with your image. Thanks to their responsiveness, flexibility and effectiveness, our dedicated team can react quickly to requests for specific samples, prototypes, 3D views, and more.

We are committed to assisting our clients with their projects, providing advice and guidance at every step and recommending quality solutions in line with their budgets. Tell us your plans and ideas. Anything is possible.

The software used by our R&D team helps you to visualise your ideas and provides you with reliable information about the feasibility of your structures. We also guarantee compliance with current standards. For each project, we work with our clients and partners to determine technical feasibility and choose finishes and colours. Our R&D team publishes the technical validation plans and 3D images. Our combination of skills and techniques ensures you enjoy a quality result.

FAQs

Order and Delivery

Yes, we deliver internationally. Shipping costs and delivery times may vary depending on the destination. Feel free to contact us for more information on delivery options.

You can order samples directly on our website through the product page of each reference. You can also contact the technical manager for your area, who can send them to you upon request.

Customization and Bespoke"

Yes. We develop specific shades for many clients. The fees for color matching are charged on a flat-rate basis. The development time ranges from 3 to 5 weeks.

Tests are carried out on a Panbeton Classic base, with medium bubbling, in A4 format. The desired color should be provided through a RAL, Pantone, NCS reference, or any other sample to be provided to us.

We create molded texts or logos directly on the panel or distributed across multiple panels.

These designs can be molded as recessed or raised, with a maximum height of 2 mm, based on a vector drawing available in .AI, .DXF, or .DWG format.

Each request is studied on a case-by-case basis, depending on the design to be reproduced, its size, etc.

A few limitations to consider:

- Minimum stroke width: 5 mm

- Minimum space between two strokes: 5 mm

- Minimum edge (distance between the edge of the panel and the end of the design): 10 mm

Customizations are not applicable to all models (see summary table on pages 82-83 of the general catalog).

We manufacture all types of bespoke fittings. Examples: counters, tables, furniture, tops, worktops, sinks, display units, etc., based on the plans supplied. On average, our Beton Lege® technology can reduce the weight of concrete parts by a factor of three. Our dedicated design office supports customers from the project feasibility study phase through to delivery of the elements, including costing and manufacturing.