Brutalism

Brutalist architectural inspiration

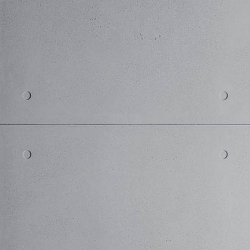

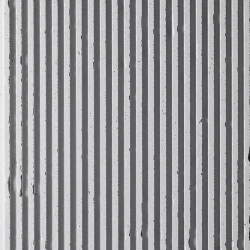

Like a tribute to the raw nature of concrete in architecture, Concrete LCDA reinterprets the building projects of the 1950s to 1970s, marked by the typical architectural style of the modern movement of Brutalism. The renowned Brutalist architects Tadao Ando and Le Corbusier are real sources of inspiration for Concrete LCDA designs. The Panbeton® range is our attempt to bring back those distinctive interior design atmospheres and conventions, namely through our Brutalist collection of decorative panels.

Applications

Products

FAQs

Characteristics

Yes. Slimbeton and Panbeton panels can be installed in humid rooms (bathroom, spa, etc.).

Our recommendations are:

- No direct contact with water (e.g., shower cabins, sink or washbasin splashes, etc.)

- Not suitable for small rooms without ventilation or excessively humid spaces such as saunas or hammams

- Use suitable adhesives – make sure to check the manufacturer's technical data to ensure water resistance.

- Apply the "S" treatment (stain + hudrofuge protection) to protect the surface (the surface will remain sensitive to direct and repeated contact with water).

- If the panel is in direct contact with a damp floor: make sure to install a waterproof baseboard.

Note:

- The effect of humidity on the structural stability of the panel over time: not studied

- The effect of humidity on the aesthetic qualities of the panel over time (surface appearance, color): not studied.

The panels can be used for exterior cladding of the fireplace. In this case, it is important to ensure that the structural backing of the Panbeton is not exposed to heat to avoid expansion.

The heat resistance of the adhesive is critical. Choose an appropriate adhesive, heat-resistant up to 70°C.

Note:

- The chimney flue must be properly insulated according to standards.

- It is possible to use Panbéton panels classified A2 with an adhesive resistant up to 90°C.

- Custom-made panels can be manufactured, with a shell (without foam to avoid expansion)

A decorative concrete panel is a wall covering made of fiber-reinforced concrete, either molded or applied to a lightweight backing. Designed to provide a modern and aesthetic finish to interior spaces, it can be customized with various textures, patterns, and colors, offering a durable and resilient solution to enhance any type of design.

Installation and fitting

Cutting is done dry, using:

- A cutting table + plunge saw equipped with a diamond blade + guide rail.

- An angle grinder equipped with a diamond blade.

For a clean, splinter-free cut, the cutting should be done with the concrete side facing up

To install our concrete panels on a wall, simply prepare a clean, dry, and level surface, then secure them with suitable adhesive or mechanical fasteners while ensuring proper alignment.

Concrete LCDA performs custom cuts directly in its workshop.

The cuts can be straight or at a 45° angle.

Note:

- It is always preferable to make at least the final cuts on-site, depending on the actual conditions of the project.

- Cuts at a 45° angle are much more fragile during handling

All types of walls or interior partitions in good condition. They must be flat, dry, and dust-free.

Depending on the nature of the surface, it may be necessary to apply a primer to improve the adhesive's bonding.

Note: If in doubt about the nature of the existing wall, it is recommended to conduct a test of adhesion beforehand.

To adhere the panels to the wall, a hybrid polymer adhesive such as Hybrifix 550 (provided by us) or an equivalent should be used.

If mechanical fastening is required by the specifications, the panels can be drilled and screwed from the front, with the screw holes then filled using the touch-up kit. A preliminary test is recommended to validate the aesthetic result.

Unlike adhesive installation, mechanical fastening does not allow for panel adjustments. Due to possible variations in panel thickness, slight unevenness may appear at the joints.

Order and Delivery

Yes, we deliver internationally. Shipping costs and delivery times may vary depending on the destination. Feel free to contact us for more information on delivery options.

You can order samples directly on our website through the product page of each reference. You can also contact the technical manager for your area, who can send them to you upon request.